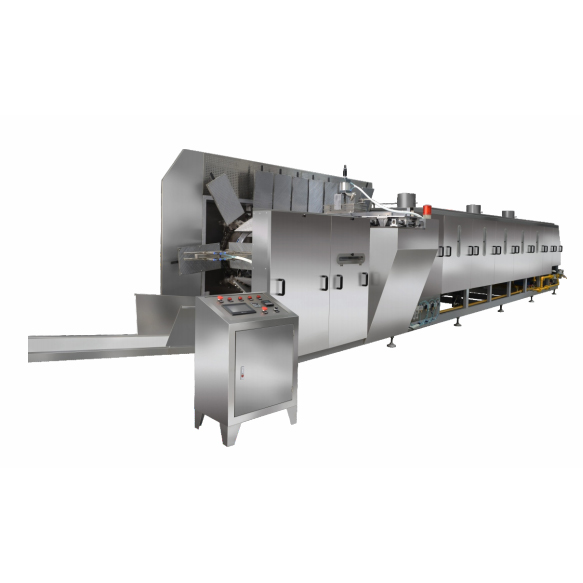

GL-10-60M (European Battercake Automatic Production Line)系列全自动煎饼生产线

Voltage: 380v

Size:9.8*1.6*1.9

Form Quantity:60Pieces

Power:3kw

Heat Consumption:natural gas14.5m3/h

liQuid gas:8kg/h

Output:3500kg/24h

Product Details

European Battercake Automatic Production Line

Purpose:

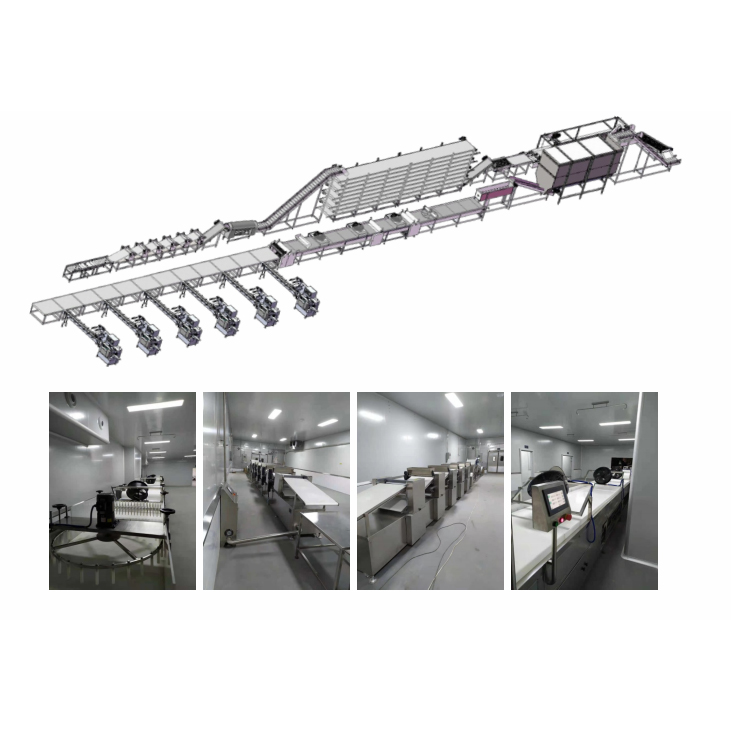

The European Battercake Automatic Production Line is a specialized industrial system designed for the high-volume, automated production of European-style battercakes (e.g., French crêpes, Dutch pannenkoeken). It streamlines the entire process—from batter preparation to cooking, shaping, and packaging—ensuring consistent quality, efficiency, and compliance with European food safety standards.

Key Applications

Commercial Bakeries & Food Factories

Mass-produces thin, uniform battercakes for retail markets, cafes, or frozen food distribution.

Customizable Recipes

Adapts to sweet or savory variants (e.g., sugar-coated crêpes, ham-and-cheese pancakes) with adjustable batter composition and cooking parameters.

Labor and Cost Efficiency

Automates repetitive tasks like batter spreading, flipping, and stacking, reducing manual labor and operational costs.

Functional Features

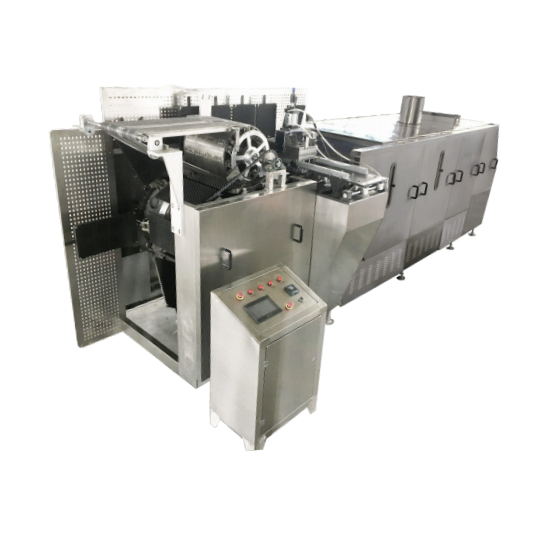

Automated Cooking Modules:

Precision-controlled griddles or rotating hotplates ensure even heat distribution for consistent texture and browning.

Integrated Process Flow:

Batter mixing → Automatic batter spreading → Cooking → Flipping/Stacking → Cooling → Packaging.

Flexible Thickness & Size:

Adjustable settings for thickness (0.5–3 mm) and diameter (15–30 cm) to meet diverse product requirements.

Hygienic Design:

Food-grade stainless steel construction with easy-clean surfaces, compliant with EU hygiene regulations (e.g., HACCP).

High Output Capacity:

Produces 800–3.000 battercakes per hour, depending on configuration.

Frequently Asked Questions about professional kitchen supplies

Q:Is Design Free?

Yes, our design is provided free of charge to each customer's specialized parents, and no fees will be charged.

Q:Are You a Factory?

We are a factory, we have an independent factory